Container Ships: History, Types, and Design Explained

Table of contents

Before containerization, moving cargo was a tedious and labor-intensive task. Each item had to be individually loaded and unloaded onto ships, making the whole process slow and costly. However, the concept of container ships brought about a revolution. The idea was simple but groundbreaking – using standardized containers to pack goods, making transportation more efficient and seamless.

Setting Sail with the First Container Ship

In 1956, the world witnessed the birth of the first purpose-built container ship – the SS Ideal-X. Converted from an old oil tanker, this container ship could carry numerous containers, making cargo handling a breeze. This innovative invention marked a turning point in the shipping industry, setting the stage for more container ships to come.

Two key factors contributed to the success of containerization – standardization and intramodality. Standardization involved using uniform containers with consistent dimensions, making it easier to move them between different modes of transportation – ships, trucks, and trains. This seamless intramodality revolutionized global trade, reducing costs, and speeding up the movement of goods.

Types of Container Ships in the Modern Maritime World

Container ships play a crucial role in the global transportation of goods, enabling the smooth flow of commodities across the seas. These mighty vessels come in various shapes and sizes, each tailored to meet specific shipping demands. In this article, we’ll explore the different types of container ships that dominate the modern maritime world.

Panamax Container Ships

Panamax container ships are named after the Panama Canal, as they were designed to fit the dimensions of the original canal locks. These vessels have a maximum length of around 294 meters, a beam (width) of approximately 32 meters, and a draft (depth in the water) limited to about 12 meters. Panamax ships have been the workhorses of international trade for several decades, efficiently carrying cargo through the Panama Canal and other similarly sized canals.

Post-Panamax Container Ships

As trade volumes grew, the limitations of Panamax ships became apparent. Post-Panamax container ships were introduced to surpass the size restrictions imposed by the Panama Canal. These vessels are larger and have dimensions that exceed the original canal’s capacity. With lengths ranging from about 300 to 366 meters, they can carry more containers, making them more cost-effective for certain routes that do not involve passing through the Panama Canal.

New Panamax (Neo-Panamax) Container Ships

The expansion of the Panama Canal, completed in 2016, allowed for the transit of larger vessels through its new locks. New Panamax, also known as Neo-Panamax, container ships are designed to fully utilize the expanded canal’s dimensions. These ships have lengths up to approximately 366 meters, a beam of about 49 meters, and a draft of around 15 meters, enabling them to carry significantly more containers than their predecessors.

Feeder Container Ships

Feeder container ships are smaller vessels that serve as an essential link in the global shipping network. These ships transport cargo between smaller and main hub ports, ensuring that goods can reach their final destinations efficiently. Feeder ships are versatile and can navigate in regions where larger container ships cannot dock due to size constraints.

Ultra Large Container Ships (ULCS)

Ultra Large Container Ships, or ULCS, are the giants of the seas. These mammoth vessels can carry an astounding number of containers, often exceeding 20,000 TEUs (Twenty-foot Equivalent Units). With lengths reaching beyond 400 meters and beams of more than 60 meters, ULCS are technological marvels. They offer significant economies of scale, reducing shipping costs per container and revolutionizing the dynamics of international trade.

Design Features of Container Ships

Container ships are the unsung heroes of international trade, silently traversing the world’s oceans, carrying goods that keep economies running. Behind their massive presence lies a carefully engineered design that maximizes efficiency, stability, and safety. In this article, we will unveil the key design features that make container ships the backbone of global trade.

Container Capacity and Stacking Efficiency

The primary purpose of a container ship is to carry as many containers as possible, efficiently and securely. The design of the cargo holds, decks, and superstructure is carefully planned to accommodate varying container sizes and weights. Engineers strive to optimize stacking efficiency, ensuring that containers can be safely piled in multiple layers without compromising stability.

Engine and Propulsion Systems

The engine and propulsion systems are the powerhouse of any vessel. Container ships are equipped with large, high-powered engines that drive massive propellers. These engines are often diesel-powered, though there’s increasing interest in exploring alternative propulsion methods, such as liquefied natural gas (LNG) or hybrid systems, to reduce environmental impact and fuel consumption.

Ballast Systems for Stability

Maintaining stability is crucial for the safe operation of container ships, especially when carrying heavy loads. Ballast systems allow the ship’s crew to adjust the distribution of water within the ballast tanks, compensating for changes in cargo weight and external forces like waves and winds. This ensures that the ship remains balanced and stable during its voyage.

Navigation and Communication Systems

To navigate the vast oceans and crowded shipping lanes, container ships rely on advanced navigation and communication systems. These include GPS, radar, electronic chart displays, and automated identification systems (AIS). These technologies enable precise route planning, collision avoidance, and effective communication with other ships and shore authorities.

Container Handling Equipment

Efficient container handling is essential for quick turnaround times at ports. Container ships are equipped with onboard cranes, gantries, and other specialized equipment to load and unload containers quickly and precisely. Modern container ships often have gantry cranes that can reach across the entire width of the ship, allowing simultaneous handling of multiple containers.

Advantages of Container Ships

Container ships have revolutionized the shipping industry and have become the backbone of global trade. Their numerous advantages have made them the preferred mode of transporting goods across continents:

- Efficient Cargo Handling: Container ships allow for efficient and standardized cargo handling. At the point of origin, one can load, secure, and seal containers, making the entire process faster and more streamlined.

- Intermodal Transportation: Containers are easily transferable between ships, trucks, and trains, enabling seamless intermodal transportation and reducing the need for repackaging at different points in the supply chain.

- Cost-Effectiveness: Containerization offers significant cost savings. When shipping bulk cargo in containers, it becomes more economical, lowering overall shipping expenses.

- Improved Security: Containers provide enhanced security for goods during transit. At the point of origin, they seal containers, and these seals remain intact until the containers reach their final destination.

- Reduced Loss and Damage: The standardized design of containers ensures that goods are protected from external factors such as weather conditions and rough handling, minimizing loss and damage during transit.

- Economies of Scale: Container ships have grown in size, allowing for economies of scale. Larger vessels can carry a higher volume of cargo, reducing the cost per container and making international trade more cost-effective.

- Faster Transit Times: Containerization and the use of large container ships have shortened transit times for goods, enabling businesses to respond more quickly to market demands.

- Global Connectivity: Container ships connect even remote regions to the global market, facilitating trade and economic development worldwide.

Challenges of Container Ships

While container ships offer numerous advantages, addressing several challenges is necessary to ensure the sustainability of the shipping industry:

- Environmental Impact: The shipping industry is, indeed, a significant contributor to air pollution and greenhouse gas emissions. Additionally, the reliance on fossil fuels for propulsion raises environmental concerns, thus necessitating the adoption of cleaner and more sustainable propulsion technologies.

- Port Congestion: The increased use of larger container ships has led to port congestion, as some ports struggle to accommodate these massive vessels and handle the growing volume of containers efficiently.

- Infrastructure Limitations: Infrastructure limitations prevent some ports from handling large container ships. Improving port facilities and investing in upgrades are essential to accommodate the growing size of container vessels.

- Piracy and Security Concerns: Container ships are vulnerable to piracy and security threats, especially in regions with inadequate maritime security measures. These risks pose a challenge to the safety of crew, cargo, and the shipping industry as a whole.

- Labor and Automation: The container shipping industry is increasingly turning to automation to improve efficiency. While automation can lead to cost savings, it also raises concerns about job losses and the need for skilled labor in the industry.

- Regulatory Compliance: Container ships must comply with numerous international regulations related to safety, security, and environmental protection. Ensuring compliance with these regulations adds complexity and cost to the shipping operations.

- Trade Disruptions and Market Volatility: The container shipping industry is susceptible to trade disruptions, geopolitical tensions, and market volatility, which can impact shipping routes, demand, and freight rates.

Container Ship Accidents and Safety Measures

Container ships are vital for global trade, but their immense size and complexity can lead to accidents with serious consequences. To ensure the safety of crew, cargo, and the marine environment, the shipping industry continually adopts stringent safety measures. Let’s explore the common causes of container ship accidents and the safety measures that help navigate towards safer seas.

Common Causes of Container Ship Accidents:

- Human Error: Human factors, such as miscommunication, fatigue, and inadequate training, can lead to accidents during navigation, cargo handling, or maintenance operations.

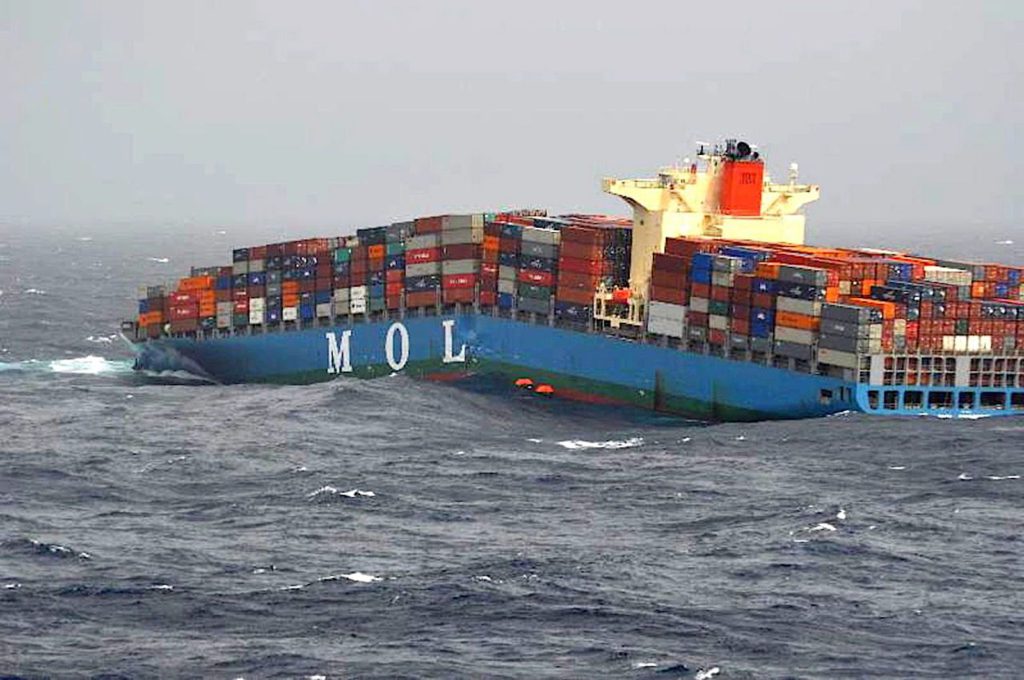

- Weather Conditions: Adverse weather, including storms, high waves, and hurricanes, can pose significant risks to container ships, especially when navigating through rough seas.

- Cargo Stability Issues: Moreover, improper stowage or securing of containers can lead to cargo shifting, ultimately causing instability and the potential capsizing of the vessel.

- Mechanical Failures: Equipment malfunctions or engine failures can compromise the vessel’s ability to operate safely.

- Collisions and Groundings: Accidents involving collisions with other vessels, structures, or running aground can cause severe damage to container ships.

- Fire and Explosions: Fire incidents, often caused by hazardous cargo or electrical issues, can be highly dangerous and challenging to control at sea.

- Piracy and Security Threats: In some regions, container ships are at risk of piracy attacks, leading to safety and security concerns.

Safety Measures in Container Shipping:

Container Ships, according to IMO have their

own list of safety measures

- Crew Training and Certification: Ensuring the presence of well-trained and certified crew members is crucial. Additionally, regular drills and training sessions significantly enhance crew competency in handling emergencies.ng well-trained and certified crew members are crucial.

- Navigation Aids and Technology: Advanced navigation systems, for instance, GPS, radar, and automated identification systems (AIS) improve situational awareness and collision avoidance.

- Stability and Loading Calculations: To keep the ship steady, it is essential to load and secure the cargo correctly. Plus, when we do the math and follow the rules, it stops the cargo from moving around.

- Safety Inspections and Audits: Furthermore, regular safety inspections and audits verify compliance with international regulations and industry best practices.

- Weather Routing Services: Access to real-time weather information and routing services helps vessels avoid severe weather and plan safer routes.

- Fire Detection and Suppression Systems: The installation of modern fire detection and suppression systems enhances the vessel’s capability to respond to fire incidents promptly.

- Security Measures: Implementing security protocols, including the use of secure areas, fencing, and trained security personnel, helps prevent piracy and unauthorized access.

- Emergency Response and Equipment: Container ships are equipped with life-saving equipment, including lifeboats and emergency response plans. These measures are put in place to ensure the safety of crew and passengers in case of accidents.

- Environmental Protection Measures: Container shipping companies adhere to strict environmental regulations. Additionally, they adopt green technologies to reduce emissions and minimize the impact on marine ecosystems.

- Safety Culture and Reporting: Fostering a safety-first culture onboard and encouraging incident reporting without fear of retribution promotes continuous improvement in safety practices.

Conclusion

To sum it up, container ships have completely changed how stuff gets from one place to another around the world. They’ve made shipping goods across the oceans faster, neater, and more efficient. Moreover, they’ve connected countries and given our economies a big boost. And as we keep coming up with new ideas to make them better for the environment, these different types of ships will stay super important for our global trade.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.