Heavy Fuel Oil Purifier | Working, Starting and Stopping Procedure

1:- Introduction to Heavy Fuel Oil Purifiers

A purifier is a machine on ships that spins fast to clean fuel and oil. It takes out water, dirt, and other unwanted stuff, keeping the oils clean. This helps the ship’s engine run smoothly and last longer.

Heavy fuel oil purifiers are essential on ships for several reasons:

- Clean fuel helps the engine run smoothly and use less fuel increasing the efficiency

- Removing dirt and water from fuel prevents engine parts from wearing out quickly.

- Purified fuel produces fewer harmful emissions, helping ships follow environmental laws it’s an important machinery for the ship in the Emission control area (SECA and NECA).

- Lower maintenance costs will be achieved by clean fuel which means fewer engine problems, saving money on repairs and upkeep.

- Consistent fuel quality keeps the engine running reliably, which is crucial for safe and timely voyages.

- Clean fuel also protects other ship equipment like boilers and generators.

- Prevents engine failure and other risks, ensuring the safety of the ship and crew.

- To learn more about Purifier, its working and overhauling, check our Purifier Package made by Chief Engineer Sunil Sir giving the complete information about purifiers.

2:- What is Heavy Fuel Oil?

- Heavy fuel oil is a thick, dark oil used as fuel on ships. It’s made from the leftover parts of crude oil after making lighter fuels like gasoline.

- HFO is used in engines because it is cheaper than other fuels and also works as an energy resource, as energy is needed for long voyages and heavy loads.

- Heavy fuel oil is a cost-effective fuel that powers ship engines, enabling them to travel long distances and carry large amounts of cargo.

- Density and viscosity of Heavy Fuel Oil used in marine engines:

- Density: 0.94 to 1.01 g/cm³ at 15°C

- Viscosity: 180 to 380 cSt at 50°C

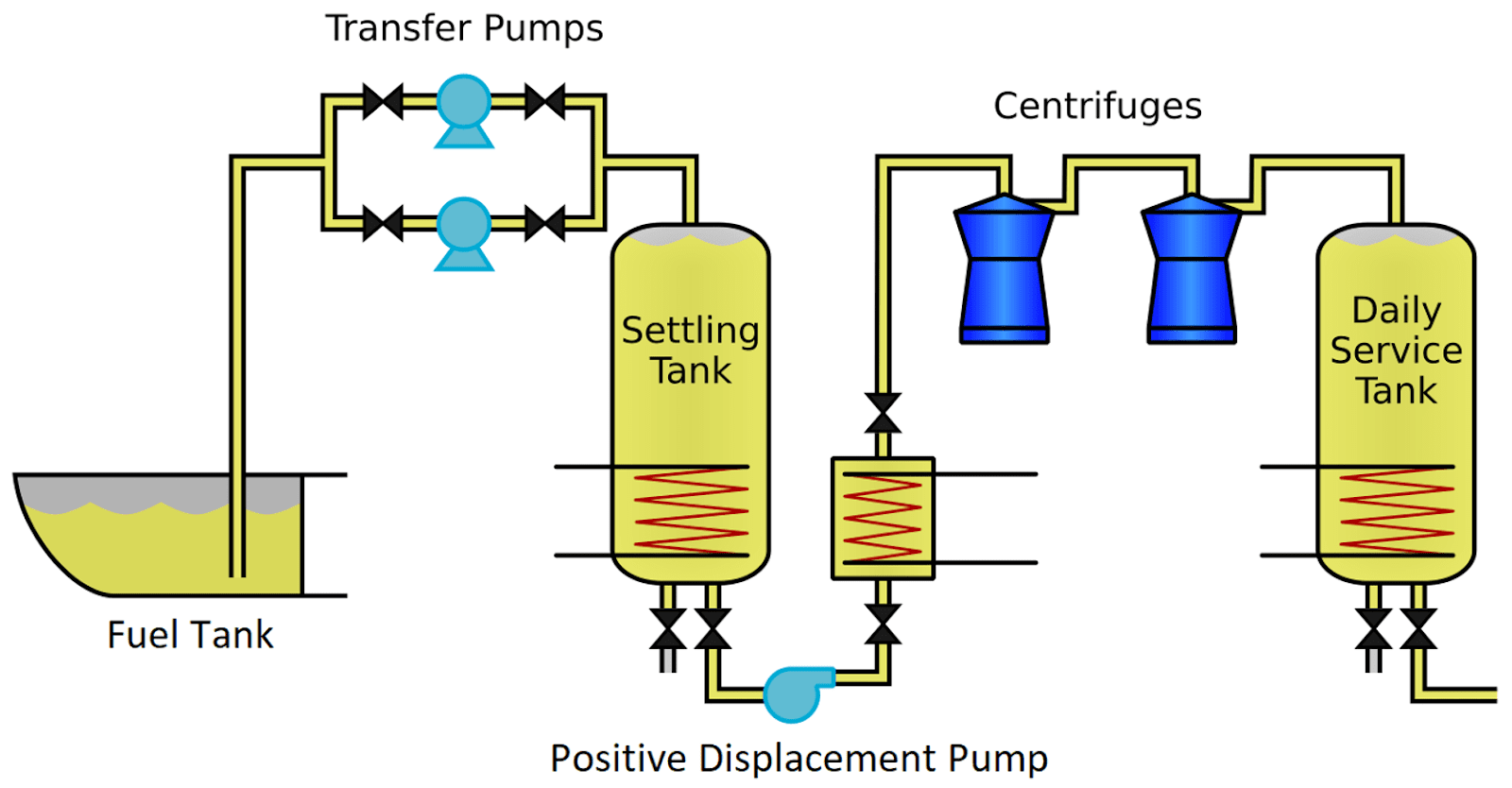

- Click Here to check out the Fuel Oil Line system onboard and its components.

2.1:- Importance of Heavy Fuel Oil Purifier

Purification is necessary for the following reasons:

- Smooth Running Engines: Clean oil makes ship engines run better, like how a clean room helps you focus better.

- Prevents Damage: Removing dirt and water from oil stops the engine from getting sick, just like washing your hands stops you from getting sick.

- Protects the Environment: Purifying oil reduces pollutants that come out of ship smokestacks, helping keep our air and oceans cleaner.

2.3:- Consequences of Using Contaminated Fuel

- Engine Troubles: Dirty oil can make engines cough and sputter, just like trying to run with a stuffy nose.

- Extra Costs: Fixing a sick engine is expensive. Clean oil saves money on engine repairs.

- Harming Nature: Contaminated fuel can pollute the air and ocean, imposing danger to marine life and the environment.

So, purifying heavy oil keeps engines healthy, saves money, and protects our planet.

3:- How do Fuel Oil Purifiers Work?

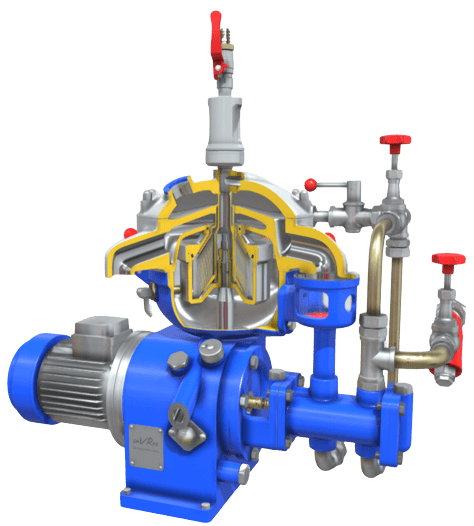

A fuel oil purifier is like a spinning box powered by a motor. Dirty fuel goes in, and because of the spinning, clean fuel and water separate from the dirt. The clean fuel and water come out, while the dirt stays behind and gets removed later.

3.1:- Working of Heavy Fuel Oil Purifier

- Separation: Dirty oil enters the purifier and spins fast inside a drum, like clothes in a washing machine.

- Centrifugal Force: The spinning creates a strong force that pushes heavier impurities, like dirt and water, to the outer edges of the drum.

- Collection: The separated impurities from a layer on the drum’s wall, like mud sticking to the sides of a bucket.

- Extraction: Clean oil collects in the center of the drum and flows out through an outlet, leaving the impurities behind.

- Disposal: The separated impurities are removed from the drum and disposed of properly, like throwing away garbage. Click here to learn about fuel storage and its distribution on ships.

- The heavy fuel oil purifier spins dirty oil to separate out impurities, leaving behind clean oil ready to power the ship’s engine.

4:- Starting and Stopping Procedure for HFO Purifier

Operating a heavy fuel oil purifier is like using a washing machine:

4.1:- Starting Procedure of HFO Purifier

- Turn on the power to the purifier.

- Open valves to let dirty oil flow into the purifier.

- Start the motor to make the purifier spin.

- Adjust settings if needed for optimal purification.

4.2:- Stopping Procedure for HFO Purifier

- Close valves to stop dirty oil from flowing in.

- Turn off the motor to stop the spinning.

- Close any open valves.

- Clean any leftover dirt from the purifier.

4.3:- Best Practices for Efficient Operation

- Regularly check for leaks or strange noises.

- Clean the purifier regularly to prevent buildup.

- Follow the manufacturer’s guidelines for maintenance.

- Monitor fuel quality and adjust settings as needed for best results.

5:- Functions of Heavy Fuel Oil Purifiers

- Cleaning Fuel: Heavy fuel oil purifiers clean the fuel used in ship engines by removing impurities like water, sludge, and solid particles.

- Optimising Engine Performance: By providing clean fuel, purifiers ensure that ship engines run smoothly and efficiently, without interruptions or breakdowns.

- Preventing Engine Damage: Purifiers help prevent engine damage by removing harmful contaminants that can clog fuel lines or cause wear and tear on engine components.

- Reducing Maintenance Costs: Clean fuel reduces the need for frequent maintenance and repairs, saving money on engine maintenance and downtime.

- Complying with Regulations: Purified fuel helps ships comply with environmental regulations by reducing emissions of pollutants like sulfur oxides (SOx) and particulate matter.

- Ensuring Safety: Clean fuel contributes to the safety of the ship and crew by reducing the risk of engine failures or accidents caused by contaminated fuel.

Therefore, heavy fuel oil purifiers play a crucial role in ensuring the efficient and reliable operation of ship engines while also helping to protect the environment and ensure safety at sea.

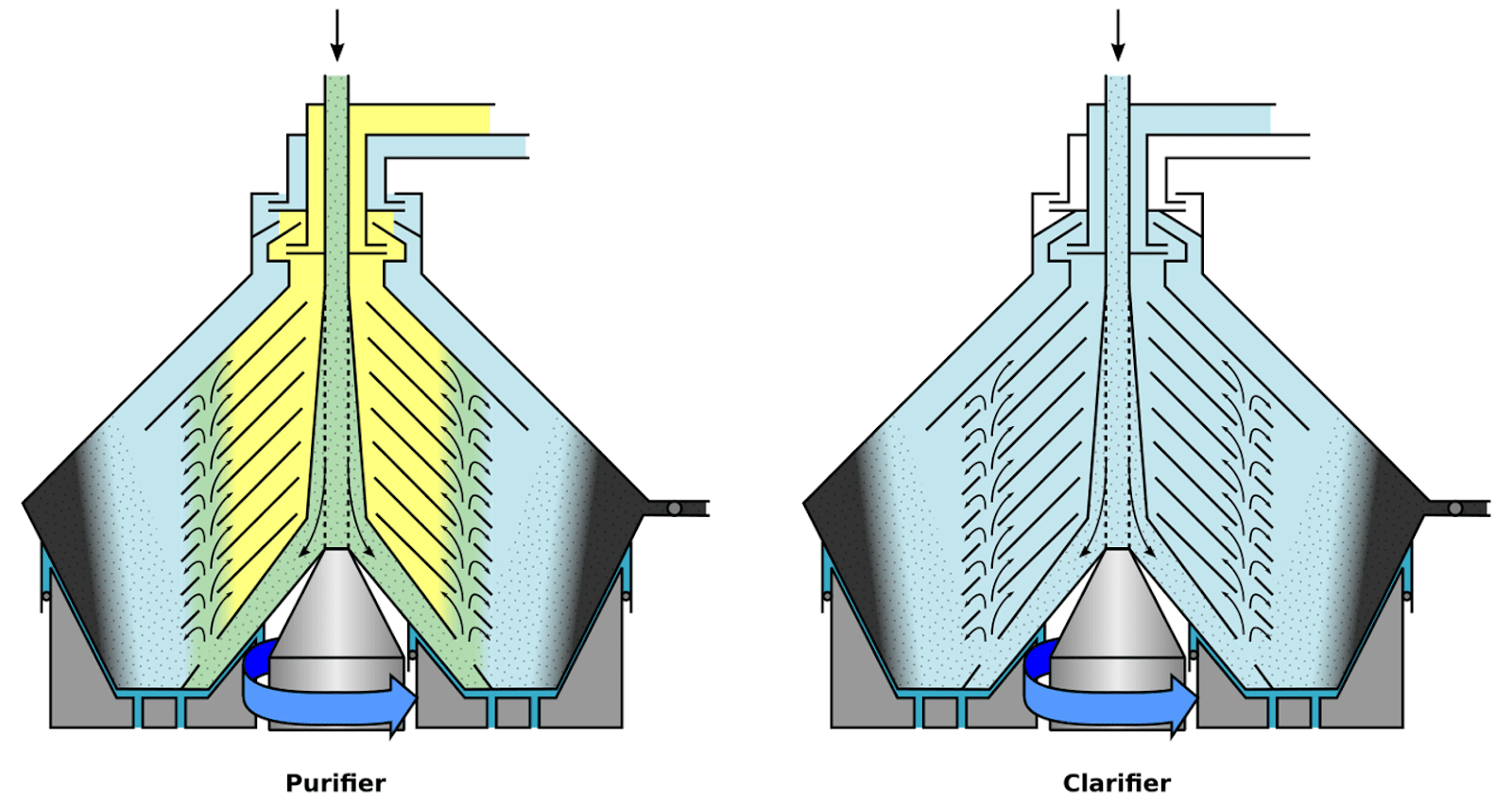

6:- Differences between purifiers and clarifiers

| Feature | Purifier | Clarifier |

| Purpose | Separates water and solids from oil | Removes fine solids from oil |

| Operating Principle | Uses centrifugal force and water seal | Uses centrifugal force without water seal |

| Separation Phases | Three phases (oil, water, solids) | Two phases (oil and solids) |

| Water Handling | Designed to handle free water | Not designed to handle free water |

| Disc Stack Design | Contains a dam ring for water discharge | No dam ring; focuses on solid separation |

| Typical Use | Treating fuel oil or lubricating oil | Removing fine solids from treated oil |

| Efficiency | High efficiency in removing water | High efficiency in removing fine solids |

| Complexity | Simpler due to the two-phase separation | Simpler due to two-phase separation |

7:- Conclusion

In wrapping up, heavy fuel oil purifiers are like superheroes on ships, ensuring engines run smoothly while keeping our oceans clean. They’re essential for keeping ships safe, saving money on repairs, and following environmental rules. As technology improves, these purifiers get even better at their job, making ships more reliable and eco-friendly.

8:- Heavy Fuel Oil Purifier Frequently Asked Questions

A heavy fuel oil purifier is a machine that uses centrifugal force to clean fuel by removing water, sludge, and other impurities. It is essential for maintaining engine performance and reducing maintenance costs on ships.

Yes, heavy fuel oil purifiers are designed to handle various types of fuel oils, including heavy fuel oil (HFO), marine diesel oil (MDO), and intermediate fuel oil (IFO).

-Wear appropriate personal protective equipment (PPE).

-Ensure proper ventilation in the purifier room.

-Handle and dispose of waste materials safely.

-Avoid contact with moving parts and hot surfaces.

-Follow the manufacturer’s safety guidelines and operating procedures.

-Regularly clean the disc stack and bowl assembly.

-Check and replace seals and gaskets as needed.

-Lubricate moving parts to reduce wear.

-Monitor for unusual noises or vibrations.

-Follow the manufacturer’s recommended maintenance schedule.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.

I will like more information

Hey Phuthi, if you want to learn more about purifiers then there is nothing which can provide you the complete knowledge about purifier than our Purifier Package by Chief Engineer Sunil Sir, where you will be able to learn the Operations, Maintenance, and Troubleshooting of Purifiers.