Enclosed Space on a Ship & Enclosed Space Entry Procedure

1:- Enclosed Space on Ship

The interior of a ship is a network of enclosed spaces that includes spaces like double bottoms, cargo tanks, pump rooms, compressor rooms, fuel tanks, ballast tanks, cofferdams, void spaces, duct keels, inter-barrier spaces, sewage tanks, cable trunks, pipe trunks, pressure vessels, battery lockers, chain lockers, blower spaces, paint locker, cargo holds (empty & laden), storage rooms for CO2, and other media used for fire extinguishing. Any enclosed or confined spaces shall be considered dangerous spaces.

2:- What is an Enclosed Space on Ship?

- Any area with limited access and exit points and maybe not enough ventilation is considered confined and could be dangerous and is referred to as enclosed spaces.

- Enclosed spaces can pose a risk for fires and explosions, trap hazardous gases, or restrict the flow of oxygen.

- Due to the small space and improper ventilation, workers and people visiting such regions often face dangers.

- The enclosed environment may cause the accumulation of harmful substances, such as methane, hydrogen sulfide, carbon monoxide, and other toxic or flammable gases.

- To safely enter and work in enclosed spaces, workers need specialized safety equipment like gas detectors, breathing apparatus, and protective clothing.

- While entering these enclosed spaces training is important to prevent accidents from happening.

3:- Common Hazards in Enclosed Spaces

- Oxygen Deficiency: Suffocation may occur from low oxygen levels in various enclosed areas in comparison to normal air. This could be caused by biological processes, chemical reactions (such as rusting or burning), or the replacement of oxygen with other gases.

- Toxic Atmosphere: Limited areas may contain dangerous vapors or gases such as ammonia, carbon monoxide (CO), or hydrogen sulfide (H2S). Inhaling these gases can be deadly.

- Fire Hazard: Methane and volatile organic compounds (VOCs) are examples of gases that can accumulate and catch fire or explode.

- Physical Dangers: Equipment that might entrap or injure people, electrical hazards, or moving machinery are all possible in enclosed environments. Other risks include slipping, falling, and getting struck by items.

- Extreme Temperature: Enclosed spaces with poor ventilation, can trap heat, leading to dangerous temperature increases. The individual may suffer from heat stroke due to the high temperature and poor ventilation.

- Electrical Hazards: Electrical systems may be present inside enclosed spaces, and exposed wires can cause electric shocks or short circuits.

- Isolation: Workers often work in enclosed spaces and may find it challenging to stay in touch with people outside of the enclosed spaces. In an emergency, this might delay help or support.

4:- Essential Safety Procedures Before Entry in Enclosed Spaces

Before entering enclosed spaces it is necessary to take safety measures, so employees can reduce the risks involved while entering and operating. Safety should always come first, with special attention given to careful planning, preparation, and following regulations.

- Appropriate Individual Make an Assessment

Before entering, the area must be inspected by a qualified individual, usually one with training in confined space safety. This involves identifying possible hazards, understanding the task to be done, and figuring out the appropriate safety precautions.

- Responsible Officer to Take Charge

The operation needs to be supervised by a designated officer. The officer oversees the work permit procedure, makes sure that all safety procedures are followed, and stays there for the duration of the operation.

- Risk Assessment

The process of risk assessment is used to recognize and manage any possible risks, especially when operating in small or enclosed areas. To protect workers, it helps to guarantee that risks are reduced and that the necessary safety precautions are in place.

- Preparing The Space For Entry

The confined space must be prepared and secured before entering. Warning boards should be placed to prevent any other person from entering. Ventilation systems should be installed to supply fresh air or remove hazardous fumes.

- Permit-to-Work

A permit to work ensures that all hazards are identified, safety precautions are taken, and only individuals with permission are permitted entry. the duty officer or the responsible officer must sign the permit.

If you want to know more about the enclosed space entry permit click here to download it.

5:- Safety Gears and Equipment for Enclosed Entry

- Using the proper safety gear and equipment is necessary for ensuring worker safety and preventing accidents when entering or working in enclosed or confined places.

- This consists of emergency supplies, monitoring equipment, and personal protective equipment (PPE).

- Self-contained breathing apparatus is used to supply breathable air from the cylinder. This allows the individual to work in conditions lacking in oxygen.

- Monitoring and Detection Equipment such as Multi-Gas Detector and Oxygen Meter is used to monitor the enclosed space for oxygen levels, combustible gases, and toxic gases like carbon monoxide (CO), hydrogen sulfide (H₂S), and methane (CH₄).

- Communication devices such as Two-Way Radios are used to communicate between the individual inside the confined space and the officer outside.

- Ventilation Equipment is used to make sure that proper ventilation is provided and toxic fumes are exhausted from the space.

- Proper lighting should be there and the equipment used should be Intrinsically Safe so even in the presence of flammable gases, they cannot ignite a spark.

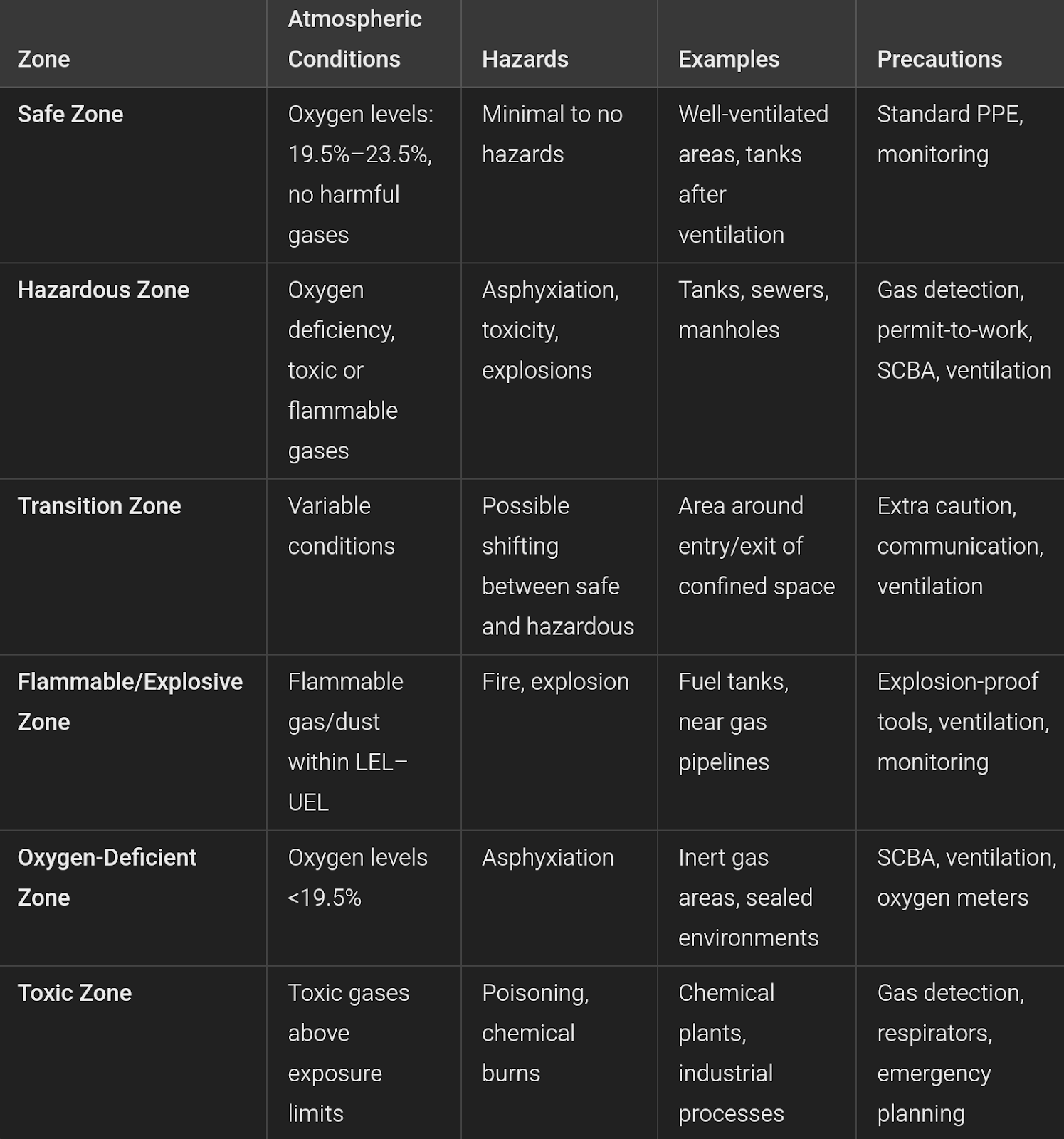

6:- Division of Zones in Enclosed Spaces on Ship

Enclosed or confined spaces can be categorised into different zones according to criteria including activity type, air circulation, and danger level. These areas are designated to ensure the proper application of safety protocols, tools, and control measures. These zones are usually established according to the presence of poisonous or combustible material, access limit, and atmospheric conditions.

6.1:- Safe Zone (Non-Hazardous Zone)

- An area where the air is considered to be safe and free of dangers such as poisonous gases, combustible objects, or low oxygen levels.

- The atmosphere is stable and the air is well-ventilated. The oxygen levels are between 19.5% and 23.5% in the safe zone.

6.2:- Transition Zone (Buffer Zone)

- The space that separates the dangerous and safe zones is known as the Transition Zone.

- This area acts as a buffer zone in case the conditions turn dangerous.

- Even though there may not be apparent atmospheric threats when entering this area, extra alertness is required.

6.3:- Hazardous Zone (Danger Zone)

- An area around a small space where dangerous conditions exist or can occur unexpectedly over time.

- Because there may be physical or atmospheric threats, this zone usually needs stricter safety precautions.

- The oxygen level is below 19.5%and flammable gases, vapors, or combustible dust is also present.

- It is necessary to continuously monitor the atmosphere with gas detectors.

6.4:- Flammable / Explosive Zone

- A zone where flammable gases, vapours, or dust are present in concentrations that could ignite and cause explosions.

- These areas require specific controls to prevent ignition sources (sparks, flames, static electricity) or can cause an explosion.

- Explosion-proof equipment and intrinsically safe tools should be used.

- It is necessary to continuously monitor the atmosphere with gas detectors.

6.5:- Oxygen-Deficient Zone

- An area where the oxygen concentration is less than 19.5%, which is hazardous to human existence.

- Due to a shortage of oxygen, the individual working may experience symptoms including anxiety, feeling lightheaded, or unconsciousness.

- Oxygen levels are below 19.5%, which can be caused by poor ventilation.

6.6:- Toxic Zone

- An area where harmful substances such as toxic gases, chemicals, or vapors are present in concentrations that could lead to poisoning, chemical burns, or other serious health effects.

- Toxic chemicals such as solvents, ammonia, chlorine, hydrogen sulfide (H2S), carbon monoxide (CO), or amounts exceeding the safe working limits are present.

7:- Importance of Regular Drills and Training

- Regular drills and training are important for working in enclosed spaces because of the high-risk involvement and even a small mistake can lead to an accident.

- The purpose of these regular drills is to ensure that crew members onboard a ship are well-prepared to respond to emergencies, follow proper procedures, and minimise risks.

- As per requirements under SOLAS Regulation XI-1/7, all vessels will need to carry out an “ENCLOSED SPACE ENTRY” drill on a 2-monthly basis.

- While conducting such drills, the atmosphere testing instruments with their accessories are to be tested and logged down in the SOLAS checklist.

8:- Conclusion

Enclosed rooms are essential to a ship’s operation, they also have significant safety hazards because of their limited area and the possibility of hazardous air conditions. A strict follow-up of procedures, such as risk assessments, the use of specialised equipment, and continuous atmospheric monitoring, are necessary to ensure safety in these areas.

9:- Enclosed Space FAQ

An enclosed space has restricted entry, and limited ventilation, and may contain hazards like toxic gases. Examples include cargo holds, fuel tanks, and pump rooms.

They can trap hazardous gases, lack oxygen, or pose fire risks. Workers are at risk of suffocation, poisoning, or injury.

Workers need PPE, gas detectors, SCBA, intrinsically safe lighting, and communication devices.

Oxygen deficiency, toxic gases, flammable vapors, and physical dangers like machinery and electrical hazards.

Every two months, as per SOLAS regulations, to prepare for emergencies.

Intrinsically safe lighting, which won’t spark in explosive environments.

Equipment should have an Ex d or Ex e rating, meaning it’s explosion-proof or intrinsically safe.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.