Fresh Water Generator on Ship

Table of contents

- 1:- Application of Fresh Water Generator on Ship

- 2:- Parts of Fresh Water Generator

- 3:- Fresh Water Generator Working Principle

- 4:- Working of Fresh Water Generator

- 5:- Types of Fresh Water Generator

- 6:- Maintenance of a Fresh Water Generator

- 7:- Safety Precautions While Operating a Fresh Water Generator

- 8:- Fresh Water Generator Troubleshooting

- 9:-Fresh Water Generator Regulations

- 10:- Conclusion

Fresh water generators are critical on ships, primarily because access to freshwater sources is restricted at sea. Ships require fresh water for various onboard uses; therefore, freshwater generation systems are critical for maintaining operations and assuring crew members’ well-being. Here’s why freshwater generation is vital for a variety of onboard purposes.

1:- Application of Fresh Water Generator on Ship

Drinking and Cooking: One of the most important uses of freshwater on ships is to drink and cook. Crewmen require a consistent supply of clean, potable water to stay hydrated and cook meals during extended voyages.

Engine Cooling: Many ships use freshwater, notably in engine systems. Freshwater helps to regulate the temperature of engines and machinery, reducing overheating and maintaining proper functioning. Steam Production: Some ships use steam for various functions, including heating, power generation, and propulsion systems. Freshwater is frequently utilized to generate steam using boilers, making it necessary for these processes.

Firefighting: If there is a fire on board, fresh water is essential for fighting it. It is used in fire suppression systems, fire hoses, and other firefighting equipment to put out fires and safeguard the ship and its inhabitants.

2:- Parts of Fresh Water Generator

Seawater Intake System: This part brings saltwater into the fresh water generator from the ocean.

Pre-Treatment System: Before seawater enters the desalination unit, the pre-treatment system filters out suspended particles, organic matter, and other contaminants. The following could be pre-treatment system components:

- Sand filters, multimedia filters, and cartridge filters are examples of filters used to get rid of suspended solids.

- Chemical dosing system: To improve pre-treatment effectiveness and safeguard downstream equipment, coagulants, flocculants, or antiscalants are added to saltwater.

Desalination Unit:- A desalination unit is a unit that produces fresh water by desalinating seawater, and is the central component of the fresh water generator. Reverse osmosis (RO), the primary desalination technology, consists of the following elements:

- Pressure vessels: These contain the semi-permeable membranes used in high-pressure desalination processes.

- Membrane Elements: Semi-permeable membranes that reject salts and contaminants but let water molecules flow through.

- High-pressure pumps: These units generate the necessary pressure to push seawater through the membrane components.

Fresh Water Storage Tanks: Onboard tanks are used to hold the freshwater produced during the desalination process for later usage. Usually constructed of materials resistant to corrosion, these tanks have level sensors installed to keep an eye on the water level.

Brine Discharge System: The concentrated brine, or reject water, that has had the salts and contaminants removed is recycled or sent overboard. Typically, the brine discharge system consists of pumps, valves, and pipework.

System for Control and Monitoring: This system uses sensors, instruments, and control panels to keep an eye on and manage the freshwater generator’s several parameters, including temperature, pressure, water quality, and flow rates. It makes sure the system runs smoothly and upholds water quality regulations.

3:- Fresh Water Generator Working Principle

Fresh water generation on ships often entails turning saltwater, which is abundant but unsuitable for consumption due to its high salt content, into drinkable water appropriate for various onboard uses. There are two freshwater generator working principle.

1. Desalination: It is the process of eliminating salt and other contaminants from seawater to create fresh water.

Both vapor compression distillation and reverse osmosis use phase transitions (from liquid to vapor or vice versa) to separate freshwater from saltwater.

2. Reverse Osmosis: Reverse osmosis makes use of a semi-permeable membrane that allows water molecules to pass through while inhibiting salt ions and other impurities. Both processes require energy input to help the separation process, which can be achieved through heating (vapor compression distillation) or hydraulic pressure (reverse osmosis).

3.1:- Fresh Water Generator Process

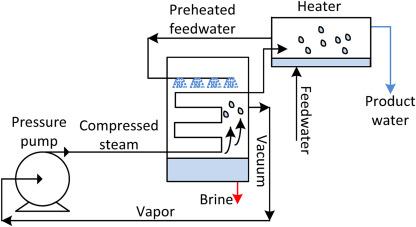

- Vapor Compression Distillation

- Seawater is boiled to produce steam, removing salt and contaminants.

- The steam is subsequently condensed back into liquid form, producing freshwater.

- This condensation process is usually aided by a series of heat exchangers and a compressor, which raises the pressure and temperature of the steam to encourage condensation.

- The produced fresh water is collected and processed as needed to fulfill drinking water standards.

2. Reverse Osmosis:

- Seawater is compressed and driven through a semi-permeable membrane.

- The membrane permits water molecules to pass through while excluding salt ions and other contaminants.

- The resulting freshwater, known as permeate, is collected on one side of the membrane, while the concentrated brine (including the rejected salts) is discharged on the opposite side.

- The permeate may go through additional treatment processes, such as remineralization and disinfection, before being considered potable.

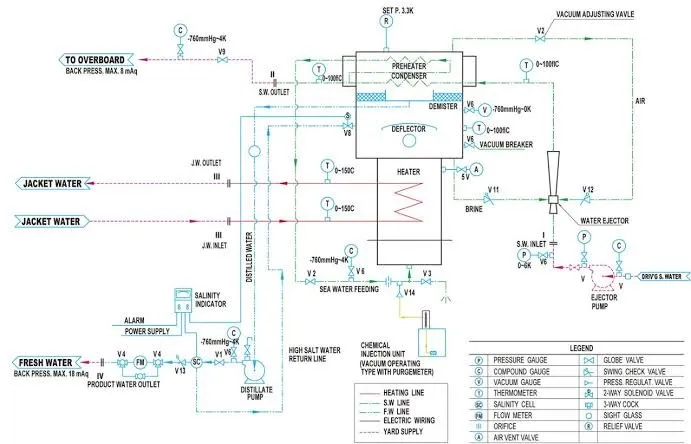

4:- Working of Fresh Water Generator

Step 1: Seawater Intake

Seawater is pulled from the ocean via an intake system on the ship’s hull.

Step 2: Filtration and Pretreatment:

Before entering the fresh water generator, seawater is filtered and pre-treated to remove suspended sediments, debris, and larger particles. This guarantees that the saltwater is free of pollutants that could degrade the quality of the produced freshwater and harm the generator’s components.

Step 3: Heat Exchange:

The pre-treated seawater is then routed via a heat exchanger and heated using steam generated by the ship’s boilers or waste heat recovery systems. This heating procedure boosts the temperature of the ocean, which aids in evaporation.

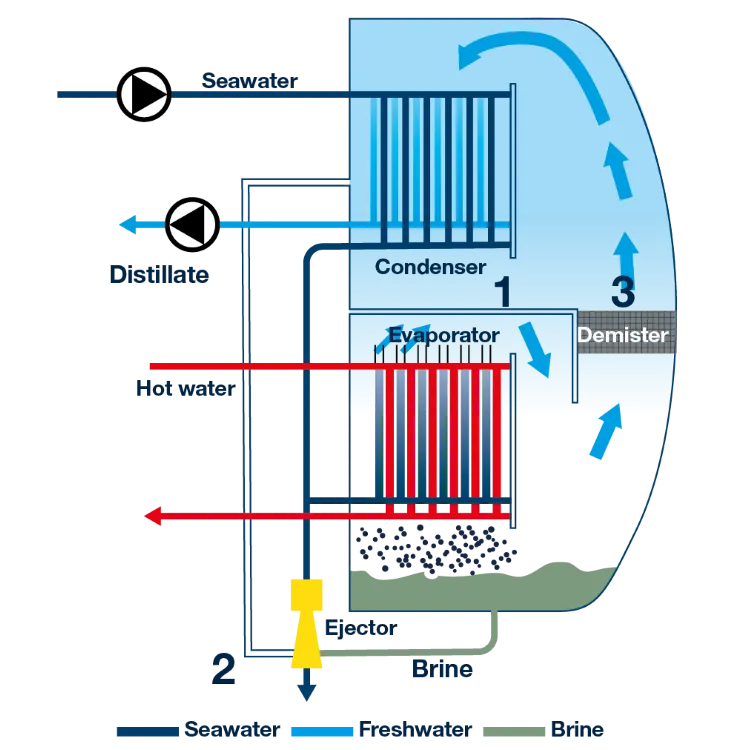

Step 3: Evaporation:

The seawater is heated before entering the freshwater generator’s evaporation chamber or distillation unit. Inside this chamber, seawater is subjected to a vacuum, lowering its boiling point. As a result, seawater boils at a lower temperature, producing freshwater vapor and leaving behind concentrated brine.

Step 4: Condensation:

The freshwater vapor formed during evaporation is condensed back into liquid form after passing through a series of condenser tubes or coils. This condensation method effectively eliminates salt and contaminants from freshwater vapor, resulting in clean drinking water.

Step 5: Collection and Storage:

The condensed freshwater is collected and directed to a storage tank or reservoir on board the ship. Here, it is held until needed for various onboard uses such as drinking, cooking, and cleaning.

Step 6: Monitoring and Control

Throughout the freshwater generation process, parameters such as seawater flow rate, temperature, pressure, and freshwater output are constantly monitored and adjusted to ensure optimal performance and efficiency.

Learn more about freshwater generators, and related machinery which will help you clear MEO Class 4 with our MEO Class 4 Package and become a better version of yourself.

5:- Types of Fresh Water Generator

5.1:- Fresh Water Generator Plate Type

Plate-type freshwater generators have many parallel plates stacked in a stack. Seawater travels between these plates, and freshwater is created using vapor compression distillation.

Advantages of Plate Type Fresh Water Generator

- Compact Design: Plate-type generators are often more compact than tube-type generators, making them suited for installations with limited space.

- Efficient Heat transmission: The closeness of the plates enables efficient heat transmission between seawater and freshwater, increasing the system’s overall efficiency.

- Ease of Maintenance: Plate-type generators may have fewer moving parts and a simpler structure, making maintenance easier and potentially less costly.

Disadvantages of Plate Type Fresh Water Generator

- Limited Scalability: Plate-type generators may have scalability restrictions, as increasing capacity may necessitate the addition of more plates or the expansion of the stack, increasing complexity and cost.

- Potential for Fouling: The thin gaps between plates can be prone to fouling from marine pollutants, requiring regular cleaning and maintenance to maintain performance.

5.2:- Tube Type Fresh Water Generator

Tube-type freshwater generators use a series of tubes through which seawater flows. Heat is delivered to the outside of these tubes to evaporate seawater, and freshwater is collected via condensation.

Advantages of Tube Type Fresh Water Generator

- Versatility: Tube-type generators can be more adaptable in terms of capacity and scalability than plate-type generators. Additional tubes can be added or removed to change the production capacity as needed.

- Reduced Fouling: Because tubes have a greater diameter than plate gaps, they may be less prone to fouling, resulting in lower maintenance requirements and more consistent performance.

- Tubes can provide better heat transfer rates than plates, potentially increasing total efficiency and output.

Disadvantages of Tube Type Fresh Water Generator

- Large footprint: Tube-type generators often have a bigger footprint than plate-type generators due to the placement of tubes and supporting structures.

- Higher Initial Cost: Tube-type generators may require a higher initial capital investment than plate-type generators, especially for larger-capacity installations.

- Tube-type generators may have a more complex construction than plate-type generators, which could result in greater production costs and maintenance requirements.

6:- Maintenance of a Fresh Water Generator

For a freshwater generator to function securely and last longer, maintenance is essential. An outline of regular upkeep duties for a fresh water generator is provided below:

- Regular Inspection: Check for wear, corrosion, or damage by visually inspecting the fresh-water generator’s parts, such as the filters, pumps, valves, and membranes. During operation, check for leaks, loose connections, and odd noises.

- Cleaning: To get rid of accumulated dirt, silt, and fouling, clean the intake screens, filters, and pre-treatment parts regularly. Maintaining cleanliness is crucial for achieving peak efficiency and averting blockages and pressure reductions inside the system.

- Maintenance of Membranes: If the fresh water generator uses reverse osmosis membranes, clean and maintains them according to the manufacturer’s instructions. To get rid of scale, biofouling, and other impurities that can lower membrane performance, this might require routine chemical cleaning.

- Chemical Treatment: To prevent scaling, corrosion, and biofouling in the fresh water generator system, put in place a chemical treatment program.

- Pressure Testing: To make sure all connections, seals, and valves are operating correctly, test the system often for leaks and pressure integrity. To avoid water loss and preserve system efficiency, take immediate action to fix any leaks or pressure dips.

7:- Safety Precautions While Operating a Fresh Water Generator

Using a fresh water generator requires handling chemicals and machinery, so it’s critical to take safety procedures to keep everyone safe and prevent mishaps. When using a fresh water generator, keep the following safety measures in mind:

- Read and understand manuals: Become acquainted with the manufacturer’s operating and maintenance manuals. Recognize the correct methods for turning on, running, and stopping the fresh water generator.

- Wear Personal Protective Equipment (PPE): When handling chemicals or carrying out maintenance duties, put on the proper PPE, such as gloves, safety glasses, protective clothes, and respiratory protection.

- Follow Chemical Handling Procedures: Comply with manufacturer instructions and safety data sheets (SDS) while handling chemicals used for pre-treatment and cleaning. Take the proper precautions when diluting, mixing, and storing materials, and keep your hands, eyes, and respiratory system away from any fumes.

- Ventilation: To avoid the accumulation of dangerous gases or vapors, make sure the fresh water generator chamber has enough ventilation. To preserve the purity of the air, install ventilation systems or exhaust fans as needed.

- Lockout/tagout procedures to secure and de-energize equipment before beginning any maintenance or repairs. To avoid unintentional startup and to isolate power sources, adhere to established protocols.

- Stay Away from Hot Surfaces: When operating, keep your distance from steam, hot surfaces, and pressured components. When doing maintenance, wait for the equipment to cool down and handle hot parts with insulated gloves or tools.

- Maintain a Close Watch on Operation: Keep a regular eye out for any unusual noises, vibrations, or changes in temperature or pressure when the fresh water generator is operating. Take immediate action to address any indications of malfunction or damage to the equipment.

8:- Fresh Water Generator Troubleshooting

The fresh water generators are crucial devices on ships that convert seawater to freshwater using a process known as desalination. Troubleshooting fresh water generator issues is critical to ensuring that drinkable water is available on board. Here are some fresh water generator troubleshooting techniques.

8.1:- Low freshwater production

- Check seawater flow: Ensure enough seawater flow to the fresh water generator. Check seawater input valves, strainers, and pumps for obstructions or failures.

- Monitor salinity levels: Determine the salinity of the freshwater produced. If salinity levels are abnormally high, it may suggest a problem with the desalination process, such as fouling membranes or insufficient pressure.

- Inspect the pre-treatment systems: Inspect pre-filtration systems, such as sand or cartridge filters, for blockage or damage. Clean or replace filters as needed.

- Inspect seals and gaskets: Check for leaks or damage in seals and gaskets surrounding membranes. Replace worn-out components to prevent seawater from bypassing the desalination process.

8.2:- High Energy Consumption

- Clean heat exchangers: Inspect heat exchangers for mineral deposits-related fouling or scaling. To restore heat transfer efficiency, clean it with chemicals or use mechanical descaling.

- Check the cooling systems: Ensure that cooling water systems are operational to maintain ideal temperatures for the desalination process.

8.3:- Membrane Fouling and Damage

- Monitor pressure differentials: A rise in pressure differentials across membranes could indicate fouling or damage. Clean membranes using chemical cleaners or replace damaged membranes as needed.

- Check for system leaks: Check freshwater and seawater pipelines, valves, and connections for leaks. Repair or replace broken components to avoid water loss and maximize system performance.

- Inspect seals and gaskets: Check for leaks or damage in seals and gaskets surrounding membranes. Replace worn-out components to prevent seawater from bypassing the desalination process.

8.4:- Control System Malfunctions

- Check the control settings: Ensure that control parameters such as feed flow rates, pressure levels, and temperature settings are properly set.

- Calibrate the sensors: To ensure accurate measurements and best system performance, calibrate salinity, temperature, pressure, and flow rate sensors regularly.

9:-Fresh Water Generator Regulations

International maritime organizations such as the International Maritime Organization (IMO) largely set norms and standards controlling freshwater generation on ships, but flag nations may impose additional national regulations. Here’s a summary of the major rules and the significance of compliance:

- MARPOL Annex VI: This regulation controls ship-related air pollution, including sulfur oxides (SOx) and nitrogen oxides (NOx).

- MARPOL Annex I: This regulation focuses on reducing pollution from oil spills and requires ships to have efficient oily water separators on board.

- SOLAS: SOLAS establishes safety standards for ships, including regulations for firefighting and lifesaving equipment. Freshwater generation systems may be required to provide enough water for firefighting by SOLAS requirements.

- Flag State Rules: Flag states may put additional rules or requirements on freshwater generation systems to guarantee that they meet international standards and handle specific environmental or safety concerns.

10:- Conclusion

To summarize, freshwater generation is critical for maritime operations, acting as a foundation for health, safety, efficiency, and environmental responsibility onboard ships. By prioritizing the construction, maintenance, and compliance of freshwater generating systems, the maritime industry can secure its personnel’s safety, safeguard the marine environment.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.