Important Precision Tools | Vernier Calipers, Micrometers, Dial Gauges

Table of contents

1:- Overview

- Precision working tools are essential in various industries, ensuring precise measurements, clean cuts, and precise construction. From machine operators to engineers, these tools are essential.

- Precision working tools are specialized for measuring equipment, a precisely calibrated gauge, or a precision cutting tool, its value is in getting desired results with maximum accuracy and control.

- These technologies make it possible to create high-quality components in manufacturing, where quality and uniformity are critical. Let us dig into the world of precise instruments and understand their importance!

2:- Vernier Calliper

2.1:- What is Vernier Calliper?

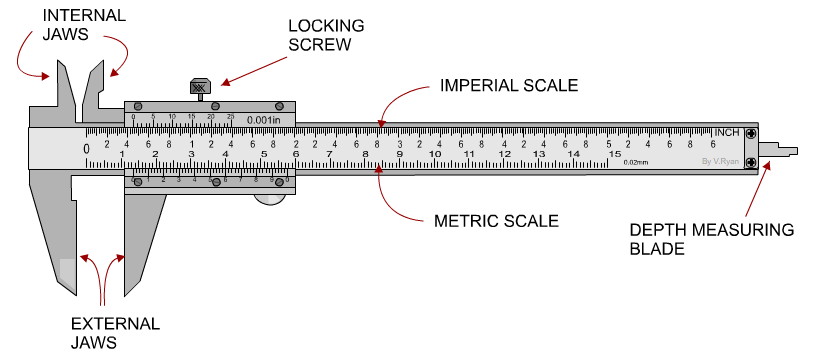

A vernier calliper is a measuring instrument used to determine linear dimensions. It is also used to measure the diameter of spherical items using the measuring jaws.

2.2:- How to Read Vernier Calliper?

- Check for Zero Error:

- Start by ensuring that the jaws of the calliper are clean and closed.

- If the main scale reading and the vernier scale reading are both at zero, there is no zero error.

- Place the Object:

- Gently open the jaws and place the object you want to measure between them.

- Make sure the object is perpendicular to the calliper’s jaws.

- Align and Read:

- Tighten the jaws until they securely grip the object.

- Look at the main scale (the fixed scale) and find the whole number part of the measurement.

- Then, check the Vernier scale (the sliding scale) for the fractional or decimal part of the measurement.

- The number before the decimal point comes from the main scale, and the number after the decimal point comes from the Vernier scale.

2.3:- What is Vernier Constant (VC)

- The vernier constant (or least count) is the difference between one main scale division (MSD) and one vernier scale division (VSD).

- Mathematically:

VC=1 MSD−1 VSD

2.4:- What is Least Count of a Vernier Calliper(LC)

- When there are (n) divisions on the vernier scale that align with (n-1) divisions on the main scale:

- LC=nVC

- For most vernier callipers, the vernier constant is 1, and the standard least count is 0.1 mm.

2.5:- Use of Vernier Calliper Onboard Ship

- It accurately measures both external and internal dimensions of objects, such as diameters of pipes, shafts, or fittings.

- Engineers use it to ensure precise manufacturing tolerances and assess the quality of ship components.

- The Vernier calliper helps identify wear, corrosion, or damage in machinery parts during maintenance.

- It verifies alignment by measuring clearances, ensuring proper fit between components.

- Engineers calibrate instruments using the Vernier calliper, adjusting settings for optimal performance.

3:- Inside and Outside Micrometer

3.1:- What is a Micrometer?

- A micrometer (also known as a micron) is a unit of length in the International System of Units (SI). It equals 1 × 10^-6 meter, which is one-millionth of a meter. In other words, a micrometer is 0.001 millimeters or approximately 0.00004 inches.

- Micrometers are used for precise measurements, such as assessing the thickness of microscopic objects, grading wool fibers, and measuring wavelengths of infrared radiation.

3.2:- Difference Between an Inside Micrometer and an Outsider Micrometer

| Aspect | Inside Micrometer | Outside Micrometer |

| Purpose | Measures internal dimensions (e.g., holes) | Measures external dimensions (e.g., diameters) |

| Construction | No U-shaped frame; uses measuring tips | U-shaped frame with fixed anvil and movable spindle |

| Formed by jaws with hardened and ground faces | ||

| Reading | Read stationary jaw and rotating thimble | Read main scale and thimble scale |

| Range | Smaller internal dimensions | External dimensions |

| Variations | Standard inside micrometer (smaller sizes) | |

| Large inside micrometer (extended range) | ||

| Applications Onboard Ship | Assessing internal components (e.g., engine cylinders) | Ensuring product quality and adherence to specifications |

3.3:- Uses of Micrometer

- Uses of Inside Micrometer

- Engineers use them to ensure proper clearances and optimal performance.

- When replacing bearings, inside micrometers verify the dimensions of bearing housings.

- Inside micrometers help determine the inner diameter of pipes, tubes, and conduits.

- Engineers use inside micrometers to measure shaft diameters accurately.

- Inside micrometers assess valve seat diameters in engines.

- Uses of Outside Micrometer

- Outside micrometers measure the external dimensions of various ship components, such as shafts, propellers, and flanges.

- When receiving spare parts, outside micrometers verify their dimensions.

- Regular measurements using outside micrometers help track wear on bearing surfaces.

- Outside micrometers assess gasket thickness during maintenance.

4:- Dial Gauge

4.1:- What is Dial Gauge?

A dial gauge, or dial indicator, is a compact mechanical instrument used to detect and display dimensional changes in a workpiece or manufactured part. It operates based on a gear and pinion mechanism,

4.2:- Parts of Dial Gauge:

- Bezel

- Bezel Clamp

- Dust Cap

- Needle/Pointer

- Scale/ Dial

- Spindle/Plunger

4.3:- Types of Dial Gauge

- Balanced Reading Dial Indicator

- Continuous Dial Indicator

- Reversed Balanced Dial Indicator

- Reversed Continuous Dial Indicator

- Plunger Dial Indicator

- Digital Dial Gauge

4.4:- Uses of Dial Gauge Onboard Ship

- Dial gauges track critical parameters such as vibration levels, alignment, and wear in ship machinery.

- Dial-type bore gauges, equipped with attached dial gauges, measure hole dimensions (e.g., cylinder bores, valve seats).

- Dial gauges verify the proper alignment of rotating machinery components (e.g., shafts, couplings).

5:- Feeler Gauge

5.1:- What is the Feeler Gauge?

A feeler gauge, also known as a gap gauge, is a precision measuring tool used to assess the clearance or gap width between two surfaces. It consists of a set of thin, flat metal strips, each marked with a specific thickness.

5.2:- How to Use the Feeler Gauge

- Select the Right Blade

- Choose a blade from the set that fits the gap you want to measure.

- Hold it at the pivot point to prevent it from folding back.

- Check Friction

- Slide the gauge into the gap.

- Feel slight friction but not too much.

- Adjust as Needed

- If it doesn’t fit, try the next smaller size.

- Rotate the set to find the right blade.

- Verify Clearances

- Use the gauge to measure gaps accurately.

5.3:- Uses of Feeler Gauge

- Feeler gauges determine the gap between components, such as bearings, valves, and piston rings.

- Feeler gauges assess wear in engine liners, cylinder bores, and other critical parts.

- During maintenance, feeler gauges check the contact between valve seats and valves.

- Engineers use feeler gauges to set precise gaps in spark plugs, injector nozzles, and other components.

5.4:- What is a Telescopic Feeler Gauge?

A telescopic feeler gauge is a specialized instrument used in areas that are remote or inaccessible to a normal feeler gauge. Here’s how it works:

- The telescopic feeler gauge consists of a long feeler gauge enclosed within a cover.

- The end of the instrument is slightly curved.

- A telescopic feeler gauge made of steel and flexible, it allows measurements in tight spaces or hard-to-reach location

6:- Trammale Gauge

6.1:- What is Trammale Gauge?

A Trammel gauge is an L-shaped instrument used for measuring various parameters, especially in the maritime industry.

6.2:- Use of Trammale Gauge on Ship

Rudder drop is the wear down of the rudder carrier bearing. It is measured by a ‘trammel gauge’.

6.2:- How Trammel Gauge work?

The Trammel gauge consists of two points:

- One point is marked on the rudder stock.

- Another point is marked on the hull within the steering gear room (often on the deck head girder).

The distance between these points is measured and recorded during construction. The difference between the original and measured points is referred to as the rudder drop or rudder wear down.

7:- Poker Gauge

7.1:- What is Poker Gauge

A poker gauge is a specialized measuring instrument used onboard ships. Its primary purpose is to measure propeller stern shaft clearance, also known as propeller wear down. This measurement helps assess the wear of the stern shaft over time. The poker gauge is typically fitted on the sealing housing, and divers use it during drydock inspections or in-water surveys.

7.2:- What are the uses of Poker Gauge?

Propeller Stern Shaft Clearance Measurement:

- The poker gauge is used to measure propeller wear down or propeller drop.

- It assesses the wear of the stern shaft over time.

- By comparing readings, engineers ensure proper clearance and maintain efficient propulsion.

8:- Conclusion

In conclusion, the precision measuring tools discussed in this blog—Vernier calipers, inside micrometers, outside micrometers, dial gauges, filler gauges, telescopic filler gauges, Trammel gauges, and poker gauges—play critical roles in maintaining ship machinery and ensuring safe navigation.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.