Propeller of Ships: Types, Working, & Construction.

A ship propeller is a unit that directly converts the rotation of the engine into thrust by moving the vessel. Picture it as a fan in water, and as it spins, it moves water to the back and that moves the ship forward. This principle works because of Bernoulli’s principle and the third of Newton’s law, where the thrust is generated by faster-moving water behind blades so that the vessel is pushed further.

1: Types of Propeller on Ship

1.1: Based on the Number of Blades

1. Three-Blade Propeller

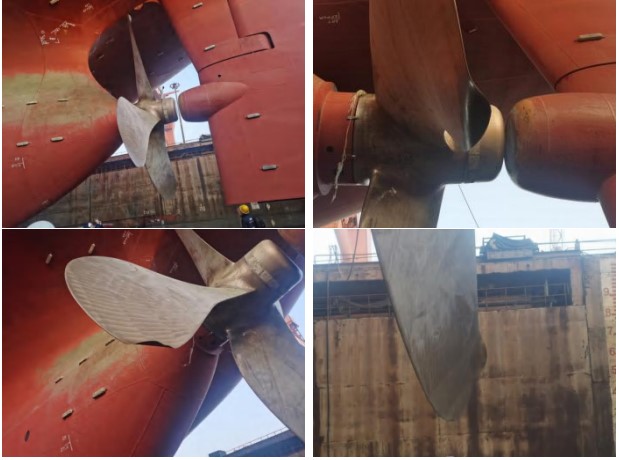

- Description: This is the most popular type of propeller with three blades.

- Characteristics: These are propellers that present a middle of the way between performance efficiency, and cost. The three-blade design gives moderate thrust and smooth operation.

- Applications: The most versatile and reliable propeller, widely used in commercial ships, cargo vessels, and fishing boats.

- Advantages: They appear more effective than two blades, giving a much smoother rotation and better fuel efficiency.

- Drawbacks: Increased drag is experienced as compared with that of a two-blade propeller.

2. Four-Blade Propeller

- Description: Four-blade propellers are much larger and heavier than their two- and three-blade counterparts.

- Features: Provide much more thrust and stability, making them ideal for vessels requiring additional power.

- Applications: Most commonly found in very large ships such as tankers and passenger vessels, where stability and reduced vibration are especially important.

- Advantages: Better performance in rough seas, less subsequent vibration, and better handling.

- Drawbacks: More expensive in production, added drag, which could affect the overall speed.

3. Five-Blade Propeller

- Description: It gives aspirational thrust through five blades and optimum efficiency.

- Characteristics: Heavy-duty applications where power and smoothness are a must-have.

- Applications: Applied in naval ships, luxury yachts, and large passenger ships.

- Pros: Excellent performance, reduced vibration, and better fuel efficiency at low speeds.

- Cons: Expensive to manufacture, heavier, may create more drag at high speeds.

- 5. Six-Blade (or More) Propeller

- Description: A propeller having six or more blades is generally rarer and is intended for only specific types of vessels.

- Features: Providing great thrust and stability.

- Applications: Used in military ships, submarines, and all such vessels requiring precision and power.

- Advantages: Maximum thrust, minimal vibration, and very high stability even under difficult conditions.

- Disadvantages: Regarded as excessively costly and not appropriate for general applications because they are heavy and complex.

1.2: Based on the Pitch of Propeller.

1. Fixed Pitch Propeller (FPP)

- Design: Has blades that are housed at a given angle and cannot be altered.

- Operation: Provides the same performance and is used in sections of the vessel that operate at a rather constant condition.

- Advantages: Very simple in design and hence easy to maintain and rather strong, and tough.

- Limitations: In this case, the angle of the blades is fixed which makes it less effective in varying operating conditions where different speeds or loads are used.

2. Controllable Pitch Propeller (CPP):

- Design: The pitch angles of the blades are not fixed and can be adjusted while in use.

- Operation: Changes the pitch of the blades to adapt to high or low rpm requirements along with the aimed operating conditions.

- Advantages: Provides more precision in steering, consumes less fuel, and can work best in all operational environments.

- Limitations: It is a quite complex device and has an adjustable mechanism, hence, it needs careful maintenance.

2: How Does a Ship Propeller Work?

A ship propeller turns the spinning energy from the ship’s engine into a force that pushes the vessel forward. Here’s how it works, step by step:

- Engine Power Transmission:

- The ship’s engine makes spinning power, which moves to the propeller through a shaft.

- Blade Rotation:

- When the propeller blades spin, they mix with the water around them.

- Pressure Differential Creation:

- The shape of the curved blades leads to different water pressures on each side of the blade.

- The front of the blade has lower pressure, while the back has higher pressure.

- Thrust Generation:

- This pressure difference creates an upward force at right angles to the blade’s surface, which pushes the ship forward along the spin axis.

- Newton’s Third Law tells us that when the propeller pushes water back, it causes an equal push in the opposite direction moving the ship ahead.

- Continuous Propulsion:

- The propeller keeps spinning, which makes water flow backward nonstop keeping up the force that drives the ship forward.

3: What is the Pitch of the Propeller?

The pitch of a propeller is the distance a propeller would move forward in one full rotation if there were no slippage, similar to how a screw moves through a solid material. It determines how much water the propeller pushes and affects the ship’s speed and efficiency.

3.1: Fixed Pitch Propellers:

- These have blades set at a constant pitch angle. This means the distance they would travel per revolution in theory stays the same.

- They work well for tasks where steady performance is enough.

3.2: Controllable Pitch Propellers:

- These let you change the blade pitch while running. This helps to get the best performance at different speeds and loads.

- They’re good for ships that need to change speed and direction often.

4: Why Propeller Pitch is Important?

- Getting the Best Performance:

- Picking the right pitch is key to reaching the speed you want and saving fuel.

- A higher pitch pushes more water each turn. This suits high-speed uses but needs more engine power.

- A lower pitch pushes less water each turn. This gives better speedup and works well for heavy loads or pulling things.

- Taking Care of the Engine:

- Incorrect pitch selection strains the engine.

- High pitch overloads the engine, while low pitch causes the engine to overrev, damaging it.

- Ship operators must understand propeller mechanics and pitch importance for efficient operation optimal performance, fuel efficiency, and engine longevity.

5: Types of Propeller Shafts

The propeller shaft sends engine power to the propeller and comes in different types:

- Tail Shaft – It’s the portion that is at the aft end of the ship and connects the propeller to the engine. The material is usually of very high strength to carry the vertical and rotary loads of the propeller. It is found in all ships where the propeller is at the dash end. It provides smooth transmission of power to the propeller along with providing support to the structure of the ship.

- Intermediate Shaft – Connect the tail shaft to the engine with different couplings. The engine-propeller distance is bridged by this component. Application It is present in the case of big vessels with long engine rooms or where the engine is not placed very near to the propeller. Benefits Reduce engine loads and allow alignment of the propulsion line.

- Thrust Shaft – This shaft is made to absorb thrust produced by the propeller and transfer it to the hull of the ship. Headed with a thrust bearing that absorbs the thrust of the propeller. Used in ships that widely \most thrust like tankers or huge freight vessels. Very helpful in the arrangement of physical support within ships to operate the thrust independently.

- Stern Tube Shaft – This shaft passes through the stern tube bearing and seals within the housing. Engineered to be water and oil-tight to prevent the leak and corrosion. Every ship provides this for an effortless operation of the propeller in submerged conditions. It makes sure that the shaft is protected from seawater but allows free rotation for the propeller.

6: Materials of a Ship Propeller

Propellers need to handle tough sea conditions, so they’re made from materials such as:

- Bronze Alloys: Often used because they resist rust and stay strong.

- Nickel-Aluminum Bronze: Gives better strength and fights off rust and cavitation.

- Stainless Steel: Offers high strength and great rust resistance good for high-performance uses.

7: What Is Heavy Running of Propellers?

Heavy running occurs when a propeller requires more power to achieve a certain speed than expected, often due to:

- Damage or Fouling: Accumulation of marine growth or physical damage can increase resistance.

- Incorrect Pitch: A pitch that’s too high can overload the engine.

- Changes in Operating Conditions: Variations in water density or temperature can affect performance.

8: Conclusion

In conclusion, the ship propeller is a vital component of marine propulsion, transforming engine power into forward thrust to drive vessels across the water. Understanding its types, materials, working principles, and key concepts like pitch and heavy running can help ensure efficient and safe operations. Whether for large cargo ships or small vessels, the right propeller design and maintenance play a crucial role in optimizing performance and fuel efficiency, making it an indispensable part of maritime engineering.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.