Sewage treatment plant | Problems faced in Sewage treatment plant

There are a lot of regulation that come under Annex IV of MARPOL. It says that the sewage or the excreta that is developed by people onboard should be treated and sent overboard into the seawater. We cannot discharge untreated sewage overboard that’s why we use sewage treatment plant.

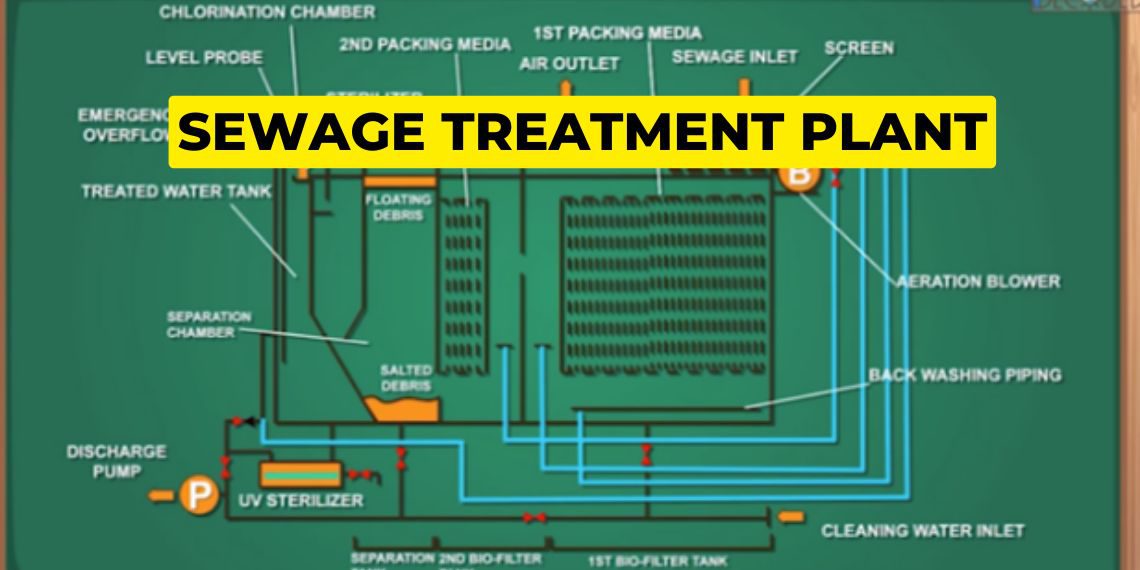

1st chamber:

Sewage from all the toilets present in the cabins when they are flushed come into the 1st chamber through the waste water line. There’s also a special line coming from the hospital on the ship. In the first chamber there’s a mesh or screen fitted so that any particular solid material which cannot be decomposed stays over there so that it does not settle down in the 1st chamber. Now the sewage goes into the 1st chamber and there’s the 1st stage packing media of mesh and in between the packing media the excreta gets stuck.

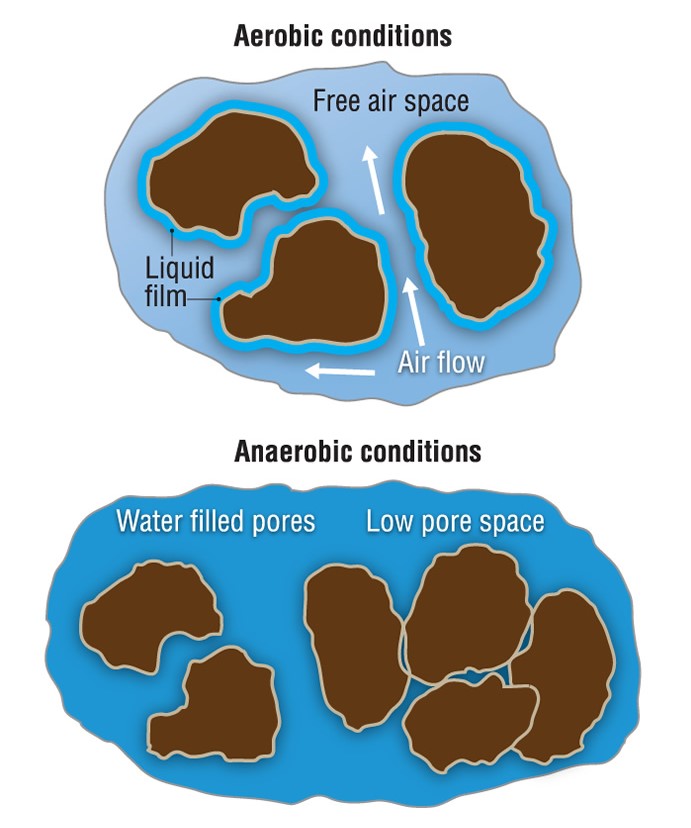

Anaerobic respiration:

Due to Anaerobic respiration when excreta starts decomposing a foul smell comes. For example suppose you go to an old place and there are drains which are chocked and you suddenly opened them, you will get a strong foul smell coming from them that is because in the drain decomposition has taken place but anaerobic respiration of bacteria is taking place i.e. they could not get oxygen so they emitted Methane and Hydrogen Sulphide gas which is poisonous as well.

Aerobic respiration:

So in the sewage treatment plant we don’t want these bacteria to go through anaerobic respiration so we provide them with sufficient oxygen so that they breathe and they liberate Carbon Dioxide gas which is not poisonous. So there’s an air blower which is taking air from the atmosphere then pressurize it and send it through various line and valves.

One line circulates the air at the 1st chamber now firstly bacteria is getting enough oxygen for aerobic respiration and secondly it is creating a circulation and when flow of air takes place it creates a vacuum due to which water comes and takes its place and the flow is maintained.

2nd chamber:

In the 1st chamber the sewage gets completely decomposed by the bacteria and little bit decomposed sludge gets into the 2nd chamber. The 2nd chamber also has a 2nd stage packing media along with it air is provided in this chamber too and again the circulation takes place and sewage gets further decomposed.

3rd chamber/separation chamber:

Now the decomposed sewage or sludge gets into the 3rd chamber but there’s no air flow in this chamber so if there is any sludge that is not decomposed it settles down in this chamber and if it is light weight like scum it will float in the top surface. This is a separation chamber so whatever remains in the middle section, it passes to the other side of the chamber.

Chlorine chamber:

But still there can be some bacteria present and we do not want them to go overboard into the sea because they might disturb the ecosystem. So there’s a chlorine chamber at the top which has chlorine tablets inside it and has holes in the chamber for passing of the sewage water which is treated, the chlorine ensures that there is no bacteria left.

4th chamber/treated water chamber:

After passing through the chlorine chamber it goes inside the treated water chamber but still we are not satisfied so it passes through a UV steriliser which kills the bacteria and ensures there’s no bacteria going overboard.

Treated Sewage is the one which passes through 1st chamber, then 2nd chamber then Separation chamber & finally Chlorination chamber.

Cleaning of packing media:

Every month we need to clean the packing media and remove the excreta which gets stuck in it to maintain proper flow and efficiency. So we do back washing, we stop all the other air valves and blow air from the bottom in the opposite way which removes all the stuck particles which have not decomposed.

Problems faced in Sewage treatment plant:

- Foaming: Foaming can occur if someone will release soap water in the toilet and flush it.

2. Smell: If there is a lot of smell coming from the sewage treatment plant that means in place of aerobic respiration there is anaerobic respiration taking place. And when anaerobic respiration takes place we have to ensure that may be there is too much sludge stuck in the packing media and we need to perform back flushing.

3. Colour: STP sample testing is carried out daily, the smell & the colour of the sample gives a clear indication of how the STP is functioning. The sample should be clear in colour, if coloured that means your sewage is not being treated properly. Then we need to perform back flushing and ensure the system is working properly.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.