Types of Marine Heat Exchangers Used On Ship

1:- What is Heat Exchanger

Onboard ship are essential to maintain the right temperature for engines and other necessary machinery. Heat exchangers are devices that help transfer heat from one medium to another, ensuring efficient temperature control.

The fundamental principle behind a heat exchanger is simple: heat flows from a hot medium to a cold one until the temperatures equalize. This process is important in ships where fluids need to be heated or cooled, such as in engine cooling systems and heating fuel oil for combustion.

2:- Heat Exchanger Definition

A heat exchanger is a device that moves the heat from one material to another resulting in the cooling of components and materials.

3:- Marine Heat Exchangers Types

There are two main types of heat exchangers used in marine systems:

- Direct Heat Exchangers: Direct heat exchangers have both media (like air and water) come into direct contact with each other, but they don’t mix.

- Example: Cooling tower- where water is cooled through direct contact with air.

- Indirect Heat Exchangers: Indirect heat exchangers have the media with separated by a wall. The heat passes through the wall without the fluids mixing. This is the most common type used on ships.

- Example: Tube type heat exchanger used onboard ship for heating lube oil increasing its viscosity to the desired level.

Want to learn about the working of Turbocharger: CLICK HERE.

4:- How Heat Transfer Works

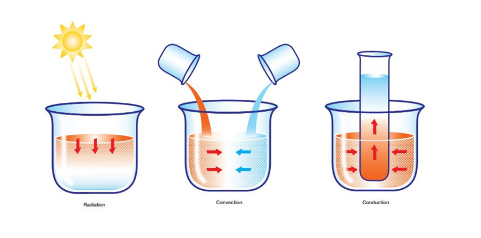

Heat transfer happens in three ways:

- Radiation: Heat is transferred via electromagnetic waves (electromagnetic radiation), an example is the heating of the earth by the sun.

- Conduction: Heat moves through direct contact between molecules, such as in solids or still fluids.

- Convection: Heat transfer through the movement of fluids. This can either be natural, relying on temperature differences or forced, like when a pump circulates fluid.

5:- How Temperature is Controlled in Marine Heat Exchangers

In marine heat exchangers, especially those using seawater for cooling, there are three common ways to control the temperature of the hot fluid:

- bypass a proportion or all of the hot fluid flow,

- bypass or limit the seawater flow;

- control seawater temperature by spilling part of the seawater discharge back into the pump suction.

6:- Types of Marine Heat Exchangers

There are several main types of indirect heat exchangers:

- Plate Heat Exchanger

- Shell-and-tube Heat Exchanger

- Spiral Heat Exchanger

6.1:- Difference between Plate Heat Exchanger and Shell and Tube Heat Exchanger

- Plate Heat Exchanger: Thin plates are used to transfer heat, and the fluids pass through separate channels. The plates are corrugated, creating turbulence, which enhances heat transfer efficiency and reduces the chance of fouling.

- Shell and Tube Heat Exchanger: These are commonly used to cool engine water and oil. Seawater passes through the inside of the tubes, cooling the fluid outside the tubes. Materials like aluminum brass are used for tubes to resist corrosion, but periodic cleaning and protection are essential to maintain their performance.

7:- Plate Heat Exchanger

- In most cases, plate-type heat exchangers are the most efficient, offering optimal solutions to thermal problems within wide pressure and temperature limits.

- A plate heat exchanger consists of heat transfer plates between a fixed and loose pressure plate, forming a complete unit with separate channels for the primary and secondary media to flow in counter-current.

- Corrugated plates create turbulence, improving heat transfer efficiency by increasing contact with the liquid and reducing the boundary layer that forms during smooth flow. The thin material and increased surface area contribute to overall efficiency.

7.1:- Plate Heat Exchanger Assembly

- Frame and plates are put together.

- Plates are positioned based on specifications.

- Tightening bolts are fitted and secured.

Titanium plates, while expensive, offer the best resistance to corrosion/erosion. Stainless steel and aluminum brass are also used, with nitrile rubber seals bonded to plates for temperatures up to 110°C.

7.2:- Advantages of Plate Heat Exchangers

- Space efficiency: This takes up much less space than a traditional shell-and-tube heat exchanger.

- Thin heat transfer surface: Results in optimum heat transfer.

- High turbulence: Higher convection leads to more efficient heat transfer and a self-cleaning effect, reducing fouling and increasing service intervals.

- Flexibility: Can be easily expanded to increase capacity and opened for cleaning (applies to gasket types, not brazed or fusion bonded units).

8:- Shell and Tube Heat Exchanger

- Shell and Tube coolers are commonly used for engine jacket water and lubricating oil cooling, typically circulating seawater inside the tubes.

- Aluminum brass (76% copper, 22% zinc, 2% aluminum) tubes are standard due to their ability to form a protective film that prolongs tube life. Baffles are used to direct liquid across the tubes and provide support.

8.2:- Key Considerations for Tube Coolers

- Materials: Tube plates are often made of naval brass and other materials like gunmetal and aluminum bronze are also common.

- Cathodic protection: Soft iron or mild steel anodes may be fitted in water boxes to reduce corrosion.

- Cleaning and Maintenance: Minimal saltwater circulation is recommended, and strainers must be regularly cleaned to avoid system blockage and erosion. For cleaning, soft brushes and chemical cleaning with approved chemicals (such as hydrochloric acid) are used.

9:- Cooling Systems of Ship

- A seawater cooling system provides water to various coolers (lubricating oil, jacket water, piston water), and excess water is discharged overboard.

- A central cooling system with low- and high-temperature circuits controls the flow and mixing of cooling water to maintain optimal temperatures.

Note

- Cooling system separate high- and low-temperature circuits for different components.

- Regulating valves control water mixing based on temperature sensors.

- Adjustable seawater flow for precise cooler efficiency.

10:- Maintenance and Cleaning of Heat Exchanger

Heat exchangers, particularly those exposed to seawater, require regular maintenance to prevent corrosion and blockages. For cleaning, soft brushes or special chemicals are used to remove deposits and maintain efficiency. Care must be taken when handling chemicals, as they can be hazardous.

In conclusion, marine heat exchangers play a vital role in maintaining the operational efficiency of ships. Their efficient design and careful maintenance ensure that critical systems onboard remain at the right temperature, keeping both machinery and crew safe.

11:- Important FAQs about Marine Heat Exchangers

Heat exchangers regulate the temperature of engines and machinery, preventing overheating and maintaining operational efficiency.

The two main types are Direct Heat Exchangers, where media comes into contact without mixing, and Indirect Heat Exchangers, where media is separated by a wall.

Plate Heat Exchangers use thin plates to maximize heat transfer, while Shell-and-Tube Heat Exchangers use tubes, typically cooled by seawater.

Temperature is controlled by bypassing hot fluid, limiting seawater flow, or adjusting seawater temperature via mixing or discharge.

Regular cleaning is necessary to prevent fouling and corrosion, often using soft brushes or chemicals like hydrochloric acid.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.