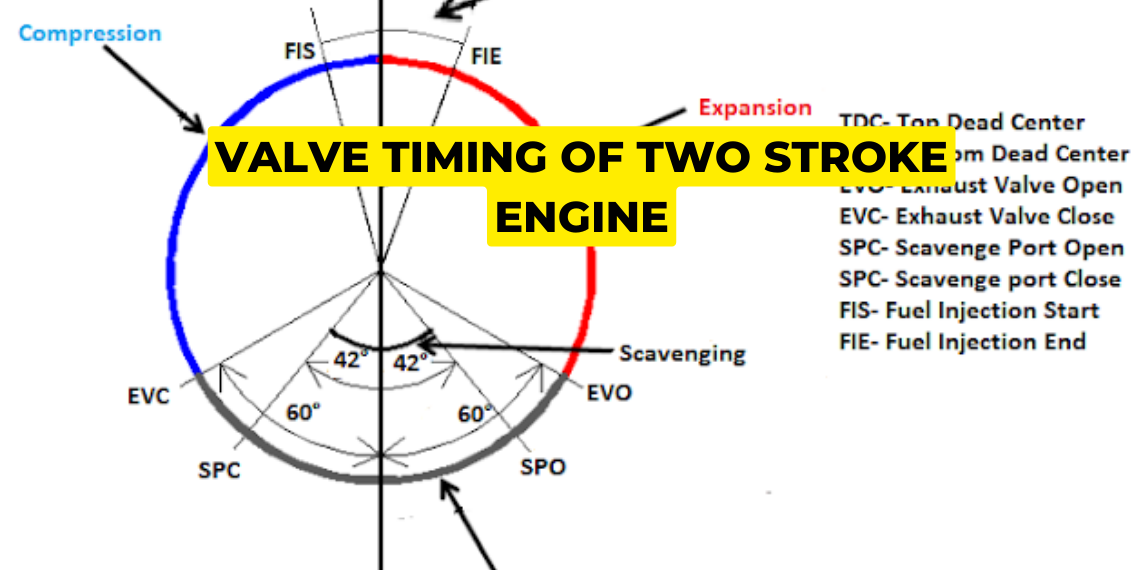

Valve timing diagram of two-stroke engine

A valve timing diagram in a two-stroke marine engine provides a graphical representation of the opening and closing timings of the intake and exhaust ports, as well as the movement of the piston, within the engine’s cylinder. This diagram is crucial for understanding the engine’s operational cycle and optimizing its performance.

The valve timing diagram aids in optimizing engine performance by ensuring efficient scavenging of exhaust gases and facilitating the intake of an appropriate fuel-air mixture. It also helps maintain proper compression ratios, enhance power output, and improve fuel efficiency, all of which are critical factors for two-stroke marine engines used in various marine applications.

1st process is that scavenge port opens 42 °C before BDC.

2nd process is that the piston reaches BDC

3rd process is that scavenge port closes 42 °C after BDC.

4th process is that the exhaust valve closes 60 °C after BDC.

5th process is that around 15 °C before TDC fuel injection starts.

6th process is that the piston reaches TDC.

7th process is that around 20 °C after TDC fuel injection stops.

8th process is that the exhaust valve opens 75 °C before BDC.

In a two-stroke marine engine, the fuel injection timing can vary depending on the quality of the fuel. When using high-quality fuel, it is advisable to inject the fuel approximately 5 degrees before the top dead center (TDC) position. However, if lower-quality fuel is being used, the fuel injection timing may need to be adjusted to around 20 degrees before TDC to ensure optimal combustion. Moreover, the fuel injection timing changes according to the throttle position. When applying less throttle, which indicates a lower power demand, the fuel quantity injected into the cylinder is reduced. This reduction in fuel quantity results in a shorter fuel injection timing, where the fuel is injected closer to TDC.

Conversely, when applying more throttle, indicating a higher power demand, a greater amount of fuel is injected, leading to a longer fuel injection timing, where the fuel is injected further in advance of TDC. By adjusting the fuel injection timing based on fuel quality and throttle position, the engine can maintain an optimal air-fuel ratio for efficient combustion, ensuring adequate power output, and minimizing emissions. It is crucial to carefully monitor fuel quality and throttle settings to make appropriate adjustments to the fuel injection timing for optimal engine performance.

Why are two stroke engines used on ships?

Two-stroke engines are commonly used as the main engines on large ships instead of four-stroke engines for several reasons:

- Power-to-Weight Ratio: Two-stroke engines have a higher power-to-weight ratio than four-stroke engines, which means they are able to produce more power relative to their weight. This is important for ships, where weight is a critical factor. Two-stroke engines are therefore capable of generating more power for the same size and weight as a four-stroke engine.

- The most important advantage of 2-stroke over 4-stroke in a ship is that they can be run either clockwise or counter-clockwise. Ships don’t have gearboxes, if you need to back your ship up, you have to shut the engine down and restart it going the other direction. You can’t do that with a four-stroke.

- Two stroke low speed engine can burn fuel of cheaper quality because of the very long stroke which adds more time for scavenging and exhaust process.

Note

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.