What is Single Point Mooring of Ship and How Does it Work?

1:- Single Point Mooring Introduction

It’s no wonder how big ships can get! Tankers, especially have gotten massive these days with the largest tankers reaching up to 400 meters in length and 70 meters in breadth. While a large quantity of oil can be carried with the help of these massive ULCCs and VLCCs, it comes with its own set of challenges. What if the discharge or loading port is not designed to handle these large vessels? What if the weather conditions do not favor these massive tankers?

To solve these problems and increase cargo transfer efficiencies, the single point mooring or the single buoy mooring system was developed in the 60s and since then, has undergone several major changes.

2:- What is a Single Point Mooring System?

A single-point mooring system is an offshore mooring arrangement where a floating vessel, such as a tanker, is anchored at a single point and yet still allows for free rotation around that point.

The SPM or Single Point Mooring System was being used for FPSOs in the 1970s and since then major advancements have taken place.

3:- Single Point Mooring Uses

The Single Point Mooring System is mainly designed to transfer liquid cargo such as oil or gas from or to an offshore floating vessel towards/a shore-based facility while rotating the ship freely around the mooring point to accommodate environmental conditions.

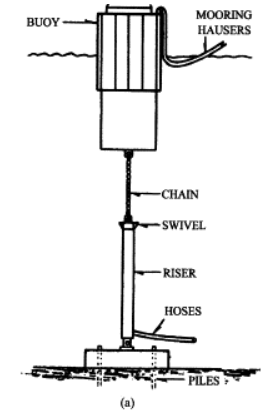

4:- Components of a Single Point Mooring System

The primary components of a typical single-point mooring system and how each of them play a vital role are discussed below

- Mooring Buoy:

The mooring of the vessel is anchored onto this floating structure. It also provides buoyancy so that the vessel can float freely around it to accommodate changes in the weather and sea conditions.

- Mooring Chains:

Heavy chains connect the buoy to the seabed, holding the system in place. They are designed to resist the forces of the wind and waves and ensure flexibility when the buoy moves with the vessel.

- Anchors:

These are set in the seabed to anchor the mooring chains. The kind and design of the anchors differ depending on the type of seabed and the actual requirements of the SPM system

- Flexible Hoses:

These are anchored to the buoy and the vessel, enabling liquids to be transferred between the two, such as oil. This flexibility will allow movement while the connection is secure enough to give way for the movement of the vessel during loading and unloading.

- Loading Arm or Hose Support:

This design accommodates the flexible hoses and attaches them to the buoy. This prevents the proper alignment of the hoses and reduces the strain that occurs during cargo transfer.

- Catenary or Semi-Submersible Configurations:

All these design configurations help stabilize the buoy while offering appropriate angles for the hoses. They enhance the flexibility and effectiveness of the mooring system.

- Control System:

This includes valves, pumps, and control monitoring devices that control the cargo flow, thus enabling safe and efficient service operation in loading and unloading.

5:- How Does a Single Point Mooring System Work?

We have tried to provide a step-by-step overview of the processes involved in single-point mooring offshore operations.

- Vessel’s Approach:

The vessel steers towards the single-point mooring buoy anchored offshore at the assigned location.

- Mooring Connection:

The oil tanker reaches out to the buoy through a mooring line or chain. A winch or deploying a small boat for support can be used to allow the vessel to connect with the buoy.

- Buoyancy and Anchoring:

The buoy with long heavy chains and anchors firmly fixed to the seabed keeps the vessel held but still gives it the freedom of movement.

- Connecting Cargo Hoses:

Next concerning the vessel, are flexible hoses attached to the buoy. Hoses have been engineered specifically for resistance against movement as well as pressure generated during the process of cargo transfer.

- Cargo Transfer:

Having the connections made and secure, crude or other liquids can then start up transferring cargo. Pumps from either the vessel or the buoy help to facilitate a controlled manner so that the flow of the cargo is managed.

- Vessel’s Movement:

As the vessel drifts from currents, winds, or waves it may pivot on the buoy, with a minimum of stress on the mooring system and hoses.

- Completion of Transfer:

The hoses are disconnected after the cargo transfer is completed and the vessel can safely disengage from the buoy

- Departure:

The vessel then moves off from the SPM and may be returning to port or going on to another destination.

6:- Advantages of a Single Buoy Mooring System

An Single point mooring system provides the following advantages:

- Operational Flexibility: Vessels can be allowed to move around or alter course depending on the mooring point that allows changes in wind and current, thus reducing collisions or damage.

- Deep-Water Capability: Deep-water operations are feasible for single-point mooring systems in situations where traditional docking is impractical, providing access to offshore oil fields.

- Reduced Port Congestion: Offshore mooring of vessels alleviates the congestion of busy ports due to the intervention of single-point mooring systems.

- Ease of Maintenance: The single point mooring can be operated without having to dry-dock the vessel, which reduces the time it spends off-line.

- Safe Cargo Transfer: The flexible hoses used for cargo transfer minimize risks associated with transferring liquids, as they can adapt to vessel movements.

- Cost-Effective: Flexible hoses in cargo transfer reduce the dangers associated with liquid cargo movement as it is flexible to move with the ship.

- Environmental Protection: The main reason that SPM systems reduce environmental impact is the fact that they don’t need extensive infrastructure and thus it does not have much chance of pollution in comparison to traditional mooring

- Quicker Turn-Around Times: Vessels using SPM can complete loading and unloading operations in about half the time of traditional methods. Typically a vessel takes about 12-24 hours for the complete operation.

7:- Limitations of the Single Point Mooring System

There is always a flip side to a coin. In the case of a Single Point Mooring System, the following limitations are posed by the system and the operations involved:

- Severe Weather: Harsh Weather conditions can disrupt the mooring operations making it unsafe for mooring and loading/unloading operations.

- High Initial Cost: Setting up an SPM system is cost-intensive due to the intricacies and man/Machine Power involved.

- Specialized Training Requirements: Due to the complex nature of the operations, Highly Skilled and Properly Trained Professionals are required to handle mooring operations of Large Tankers

- Environmental Risks: Although Designed to minimize environmental risks, SPM Installations still pose a threat of environmental disaster in the way of oil spills due to leaks, hose ruptures, and often, human errors.

8:- FAQs Regarding Single Point Mooring

Single Point Mooring or SPM is a floating buoy or jetty, anchored offshore to facilitate the transfer of Oil cargo and Crude oil from shore-based facilities and offshore platforms to ships.

Mooring Buoy, Mooring Lines and Anchors, Flexible Hoses, Subsea Pipelines & Swivel Systems are the components of the SPM System that are used to dock the ship offshore and transfer cargo.

Single Point Mooring is used by large oil tankers, primarily Ultra Large Crude Carriers(ULCCs) and Very Large Crude Carriers(VLCCs).

India has several ports with the facilities of Single Point Mooring available in Vadinar, the Mumbai Offshore terminal, Kochi, Kandla, Paradip, Haldia, Mangalore, and Dhabole.

Yes. Both are essentially the same and often interchangeably used terms.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.